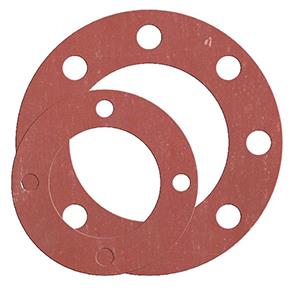

The graphite gasket is cut or stamped from pure graphite plate or metal (tooth plate, flat plate, mesh) reinforced graphite plate. It has many outstanding sealing properties, such as: thermal stability, self-lubrication, corrosion resistance, no aging, no hair It is brittle and so on. It can be used for a long time under severe working conditions, and it requires little maintenance. The lining information can be selected from different metal sheets. The type can be selected without edging, inner wrapping edge, outer wrapping edge and inner outsourcing edge. Graphite slitting gaskets are perforated or cut from pure graphite sheets. They have outstanding corrosion resistance, high/low temperature resistance, outstanding compression resilience and high strength, and various round shapes. Miscellaneous gaskets are widely used in pipes, valves, pumps, pressure vessels, heat exchangers, condensers, generators, air compressors, exhaust pipes, refrigerators, and the like.

It is used in various industrial pipe flanges, heat exchangers, bonnets, etc., as well as special shape flanges on liquid level gauges and level gauges.

The graphite gasket is made of graphite wire and is shaped by weaving. Graphite gaskets are suitable for stuffing box seals of various valves, pumps, reactors and other equipment operating under high temperature, high pressure and strong corrosive media.

Expandable graphite (flexible graphite) is chemically treated with very natural graphite and treated at a high temperature of 1000 ° C. This material provides excellent heat resistance and chemical resistance, and it is very good for the gasket to have high elasticity and low elongation. Sexual characteristics.

1. The sealing performance of the flexible graphite gasket is almost unchanged in the range of extremely low temperature to 400 °C;

2. Flexible graphite gaskets have excellent chemical resistance to almost all liquids (except for strong oxidizing acids);

3. Due to the cold deformation and ductility, the installation is too tight and has no effect on the flexible graphite gasket.

Flexible graphite gaskets are cut from flexible graphite sheets (or with metal reinforcement) and are divided into four types depending on the application:

1. Flexible graphite gasket: cut from flexible graphite sheet for pipe flange and bonnet. It is recommended that these gaskets be small diameter gaskets depending on their low mechanical strength.

2. Flexible graphite gasket MI: The hooked carbon steel sheet (0.2 mm thick) is sandwiched between flexible graphite sheets and then cut to a specific scale with high mechanical strength.

3. Flexible graphite gasket PM: The flexible graphite sheet is adhered to both sides of a 0.2 mm thick 304 stainless steel sheet, which has high mechanical strength and is easy to transport, since it can also be cut into a messy shape. Gaskets are widely used in various industries.

4. Flexible graphite gasket PM-A: Replace the stainless steel sheet in T/#1215 with 316 steel (50 micron).

Related News

- Analysis of future development trend of graphite gasket

- The necessity of metal wound gaskets in the use of industrial flanges

- Metal spiral gasket purchase notice

- Metal winding gasket production process analysis

- Selection and installation points of metal wound gasket

- Metal spiral gasket production process

- Main use of graphite packing

- How much do you know about graphite packing classification?

- What is the market development prospect of metal wound gaskets?

- The difference and characteristics of graphite gasket

- Take you to know the winding mat