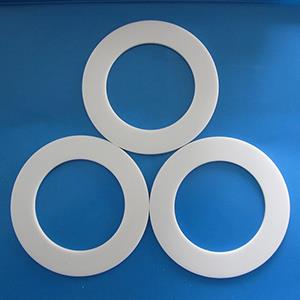

PTFE gasket

PTFE gasket Peng Nuo PN1900

PTFE gaskets, also known as PTFE gaskets, are also called PTFE gaskets or Teflon (Teflon, Teflon) gaskets. The PTFE rods, tubes and plates are mechanically turned or cut. Flat gaskets, V-shaped gaskets, piston rings, ball valve gaskets, etc. can also be molded by molding at a high temperature to form a molded PTFE gasket. Because PTFE has excellent corrosion resistance, aging resistance, insulation, cleanliness and other good characteristics, it is widely used in many fields such as chemical, petroleum, pharmaceutical, food, etc., and is called "plastic king". PTFE has extremely strong anti-corrosion properties, and only a few elements such as molten alkali metal and high-temperature, high-pressure elemental fluorine act on it. PTFE does not absorb water, is resistant to oxygen, and has good weather resistance. When exposed to outdoor for 3 years, the tensile strength remains almost unchanged, and only the elongation rate decreases. Due to the cold flow and creep phenomenon of PTFE under pressure and high temperature, it is very suitable for the sealing part which is corrosive at low pressure or low temperature or does not allow pollution. PTFE can be processed into different shapes of PTFE products at a temperature between -100 ° C and 100 ° C. It can also be used in combination with other materials such as PTFE coated gaskets, wound gaskets, or as A metal-based gasket, such as a metal toothed combination mat and a metal-toothed composite gasket.

Note: PTFE gaskets become brittle at temperatures below -185 °C, creep cracking above 200 °C, so they should not be used at excessive temperatures. The PTFE gasket has a low thermal conductivity and a large coefficient of linear expansion. Under the load, cold flow will occur. It is recommended to use it on the uneven surface of the medium temperature and low pressure, the full plane and the groove flange. If the water line effect is better. . Adding different fillers such as glass fiber, graphite, molybdenum disulfide, bronze powder, etc. can improve the performance of PTFE gaskets. Refer to modified PTFE gaskets.

Performance characteristics:

1. Strong acid resistance. Strong alkali, almost resistant to all chemical media, except for molten alkali metals and elemental fluorine.

2. Excellent insulation performance, good aging and weather resistance.

3. Low friction coefficient, easy to bond, easy to install and disassemble

4. The product is clean and can be used for sealing parts that are not allowed to be contaminated by food, medicine, etc.

5. High mechanical strength, good turning performance and easy processing into different sealing products.

6. The coefficient of linear expansion is low. It is prone to creep or stress relaxation when cold flow occurs at high temperature after compression. It is not suitable for high temperature and high pressure parts.

PTFE gasket used in the industry: chemical, petrochemical, refining, chlor-alkali, acid, phosphate, pharmaceutical, pesticide, chemical fiber, dyeing, coking, gas, organic synthesis, non-ferrous smelting, steel, atomic energy and high-purity products (such as ions Membrane electrolysis), the transportation and operation of viscous materials, and the processing and production departments of food and beverages with strict requirements for hygiene.

Use equipment: sealing parts of flange joints such as pipes, valves, pumps, pressure vessels, heat exchangers, condensers, generators, air compressors, exhaust pipes, refrigerators, etc.

Technical standards for PTFE gaskets:

GB/T 9126-2008|Non-metal flat gasket size for pipe flange

GB/T 17727-08|Non-metal gasket size for marine flanges

HG/T 20627-2009|Non-metal flat gasket for steel pipe flange (Class series)

HG/T 20606-2009|Non-metal flat gaskets for steel pipe flanges (PN series)?

QB/T 3626-1999|Teflon bar

QB/T 3625-1999|PTFE sheet

HG2-234-76 polytetrafluoroethylene (PTFE) resin technical standard

QB/T 3624-1999|Teflon tubing

JB/T 10688-2006|Technical conditions for PTFE gasket

Available in any standard and non-standard sizes, including ASME, DIN, JIS, GB and other standards. Available in round, square and other shapes, and reinforced strip PTFE gaskets are available upon request.