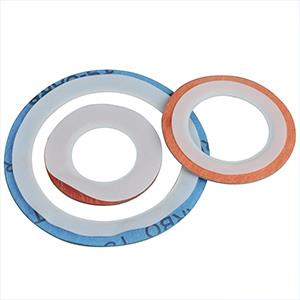

PTFE sandwich pad

PTFE coated gasket Pengnuo PN2000

PTFE coated gasket, also known as PTFE coated gasket is a non-metallic gasket, generally composed of two layers of cladding and embedded. The coating is mainly resistant to corrosion, usually made of polytetrafluoroethylene material, and the insert (filler) is a non-metallic sealing material with or without a metal reinforcing layer, usually asbestos rubber sheet, non-asbestos. Rubber sheet, graphite composite board, etc. PTFE-coated gaskets are mainly suitable for full-plane and protruding-face steel pipe flange connections. They are suitable for corrosive media with nominal pressure PN of 0.6-5.0 MPa and working temperature of 0-150 °C or for cleanliness. Higher required media. The gasket is divided into V type, U type and L type according to the inner core structure. Some containers, pipes, and valves in the petroleum, chemical, pharmaceutical, and food industries are often sealed with Teflon gaskets to ensure material cleanliness.

※ Note: Due to structural reasons, the PTFE coated gasket is thinner in the coating layer, so it is prone to cracking during installation and use, causing the medium to penetrate into the core material in the embedded layer to cause erosion. Therefore, it is recommended to replace the gasket frequently or use a modified PTFE gasket or expanded PTFE gasket in the important sealing parts.

PTFE sandwich gasket performance characteristics:

1. Combines the different characteristics of the inner core material and the corrosion resistance of PTFE

2. Low friction coefficient, easy to bond, easy to install and disassemble

3. The product is clean and can be used for sealing parts that are not allowed to be contaminated by food, medicine, etc.

4. Good compression resilience

PTFE sandwich gaskets used in the industry: chemical, petrochemical, refining, chlor-alkali, acid, phosphate, pharmaceutical, pesticide, chemical fiber, dyeing, coking, gas, organic synthesis, non-ferrous smelting, steel, atomic energy and high-purity products ( Such as ion-exchange membrane electrolysis), the transportation and operation of viscous materials, and the processing and production departments of food and beverages with strict requirements for hygiene.

Equipment used: sealing parts of flange joints such as pipes, valves, pumps, pressure vessels, heat exchangers, condensers, generators, air compressors, exhaust pipes, refrigerators, etc.

PTFE coated gasket marking example

Machining type PTFE coated gasket with nominal size DN100 and working pressure PN40, core material is XB450 asbestos rubber sheet, marking example: HG/T20607 PTFE coated gasket (XB450) B 100-40

Cut-off type PTFE coated gasket with nominal size DN200 and working pressure PN10, core material is nitrile rubber gasket, labeling example: HG/T20607 PTFE coated gasket (NBR) A 200-10

Folding type PTFE coated gasket with nominal size DN600 and working pressure PN6, core material is XB450 non-asbestos rubber sheet, labeling example: HG/T20607 PTFE coated gasket (NAS) C 600-6

Technical standard for PTFE sandwich gasket:

GB/T 13404-2008|Teflon-coated gasket for pipe flange?

HG/T 20628-2009|Teflon-coated gasket for steel pipe flange (Class series)

HG/T 20607-2009|Teflon-coated gasket for steel pipe flange (PN series)

SH 3402-1996|Teflon-coated gasket for pipe flange?

Available in any standard and non-standard sizes, including ISO7483, EN 1514-3-97, ASME, DIN, JIS, GB and other special requirements.