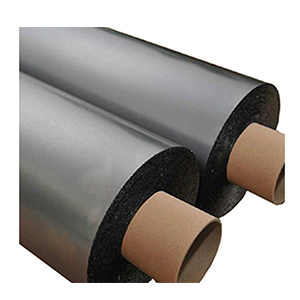

Flexible graphite paper

Flexible graphite coil (paper) Peng Nuo PN5000

Flexible graphite coils, also known as flexible graphite paper or flexible graphite sheets, are chemically treated with natural graphite scales and then expanded by heating to form graphite worms. The density of such insect-like graphite powder is about 0.003 g/cc. A flexible graphite web is then formed by rolling. Flexible graphite coils contain no binders and fillers, so they are highly pure, have good corrosion resistance, are resistant to radioactivity, are resistant to high/low temperatures, have good compression resilience, and are self-lubricating and impervious. Sealing at low pressure parts. Graphite coils and sheet metal can be composited into various forms of graphite composite sheets.

Graphite coil performance characteristics:

1. Excellent heat resistance and cold resistance. Flexible graphite from the ultra-low temperature of -270 degrees to 3650 degrees (in non-oxidizing gas) high temperature, its physical properties have almost no change, can also be used in air around 650 degrees;

2. Excellent chemical resistance. In addition to corrosion in a strong oxidizing medium such as aqua regia, concentrated nitric acid, concentrated sulfuric acid and high temperature dichromate, potassium permanganate or ferric chloride, flexible graphite is resistant to almost all inorganic and organic media;

3. Have good self-lubricating properties. Like the natural graphite, the flexible graphite is easy to produce sliding under the action of external force, so it has lubricity, good wear-reducing property and low friction coefficient;

4. The rebound rate is high. When the shaft or bushing has a radial circular runout due to eccentricity in manufacturing, installation, etc., it has sufficient floating performance, and even if the graphite is cracked, it can be well adhered, thereby ensuring tightness and preventing leakage.

5. The expanded graphite gasket has low requirements on the flange surface, and the small pre-tightening force can achieve the sealing effect. The cutting is easy to be a more economical and practical gasket.

Applications:

1. Can be used as graphite packing ring material

2. It can be combined with a thin metal plate to form a graphite composite plate and cut into various shapes of gasket.

3. It can be used directly for making various low-pressure gaskets or processing into thick plates for high-temperature insulation pads.

Common specifications for graphite coil:

Width 1000mm or 1500mm, coil length 30, 50, 80m; coil weight: 40kg / roll sheet thickness 0.1mm-50mm; density, 0.8-1.25g/cm3, other special specifications customers can request.

Graphite coil technical standards:

JB/T 7758.2-2005|Technical conditions for flexible graphite sheets

JB/T 53392-1999|Quality classification of flexible graphite sheet products

JB/T 6613-2008|Flexible graphite sheets, strips, classification, code and marking

JB/T 9141.4-1999|Test method for compressibility and rebound rate of flexible graphite sheets

JB/T 7758.4-2008|Method for determination of chlorine content in flexible graphite sheets

JB/T 7758.3-2005|Method for determination of sulfur content in flexible graphite sheets

JB/T 9141.1-1999|Flexible graphite sheet density test method

JB/T 9141.6-1999|Method for determination of carbon content in flexible graphite sheets

JB/T 9141.2-1999|Test method for tensile strength of flexible graphite sheets

JB/T 7758.7-2008|Flexible graphite sheet stress relaxation test method

JB/T 9141.7-1999|Method for measuring thermal weight loss of flexible graphite sheets

Available in any standard and non-standard sizes, including ASME, DIN, JIS, GB and other standards. Available in round and square shapes, and available in special sizes for graphite coils.